Customer help

email or give us a call on 0333 210 6737.

This section is to help with any queries you may have regarding product information, finance and delivery of our products.

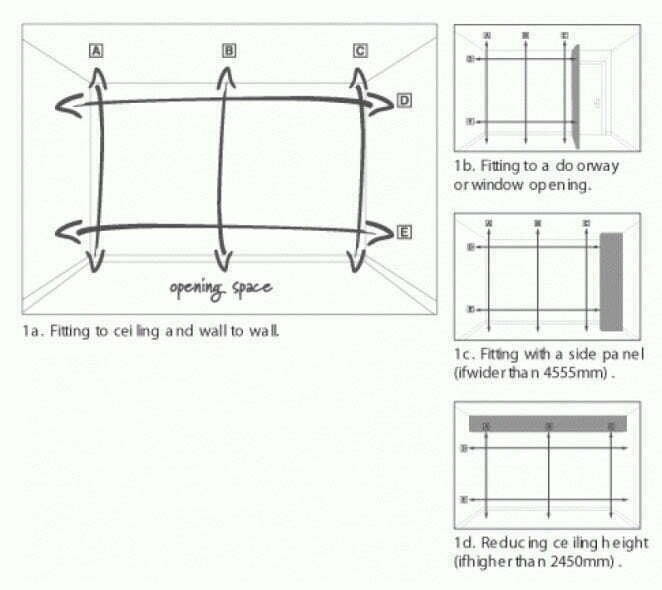

1. How to measure up for made to measure doors

Measure your opening height and width at the five points indicated on the main diagram below.

Do this at approx. 620mm away from the back wall. of where your Sliding Doors will go to allow for your interior system.

Minimum Door Width: 400mm (depending on door range)

Maximum Door Width: 1220mm (depending on door range)

Maximum Opening Height: 2480mm – can be extended to Max. Opening Height 2750mm (certain ranges)

Maximum Opening Width: 4880mm (minus door overlaps)

Note: If there is a difference between the measurements of heights A, B or C, this means that your ceiling and door are not parallel. Your track-set will allow for a difference o up to 15mm, but if the difference exceeds this you will need to make adjustments to your ceiling or floor (See diagrams 1b, 1c, & 1d).

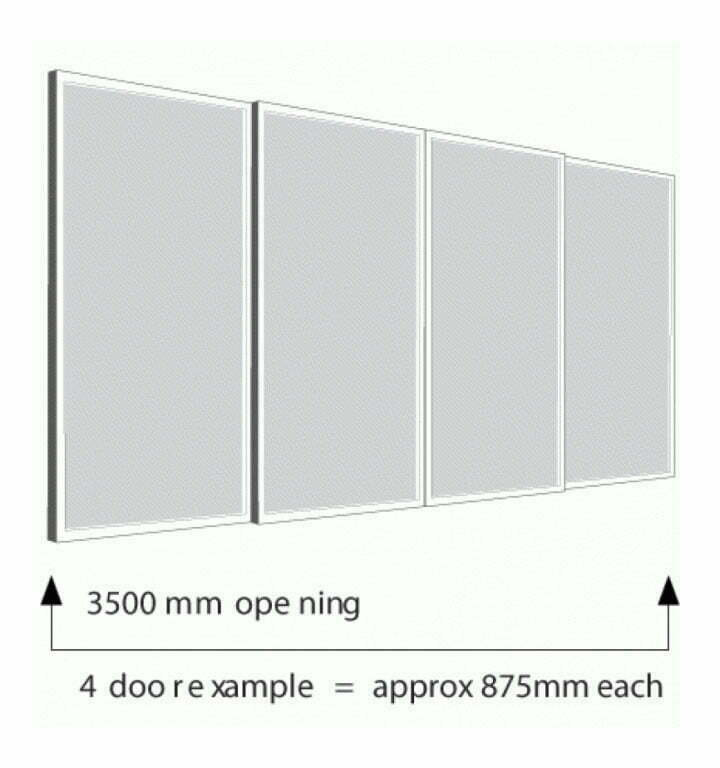

2. How many doors do you require

As long as your chosen doors falls within the sizing dimensions in step 1, then you can have as many doors as you like. (Your door measurements will vary slightly due to the amount of overlaps that will be required, but this is something we will calculate these for you, keeping this process simple).

NB: If you wish to use a 900mm wide drawer for your interiors, either from the Aura or Alutec range, your door sizes must be wider than 930mm to allow the drawers to be opened. This also applies to any interior product which needs to be pulled out towards you.

For example: If your opening width is 3500mm and you would like 4 doors, each door would approx. be 875mm wide.

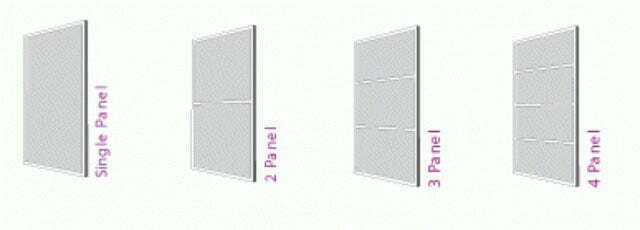

3. Panel combination guide for Made to Measure Doors

Create your own unique look by combining the different frame finishes with the variety of panel options, within each made to measure

door style.

Made to measure wardrobes size information

- E Top Track for easy installation and adjustment

- Maximum opening height of 2480mm, extendable to 2750mm (certain ranges)

- Minimum recommended opening height of 1200mm

- Maximum Opening width of 4880mm

- Maximum door width of approx. 1220mm

- Minimum recommended door width of 400mm

When installing, the Floor Track should be fitted back level with the back of the Top Track

Generally we will build your doors so that the overlap between front and rear doors is the same as the width of the door frame although this can be more depending (however if you require each door to be a specific width please send us an e-mail with this detail) We do this for aesthetic reasons only. You may notice that the door visualizer shows no overlap. This is just due to limitations in the software.

Made to measure wardrobes overlap and frame widths

- BUDGET = 24mm Steel Frame

- HERITAGE = 26mm Steel Frame

- CLASSIC = 35mm Steel Frame

- NEPTUNE = 34mm Steel Frame

- SHAKER = 75mm Steel Frame

- MIRAGE = 36mm Aluminium Frame

- HERITAGE LOFT = 27mm Aluminium Frame

- ALPHA = 32mm Aluminium Frame

- REFLEX = 12mm Aluminium Frame

- TESS MINIMAL = 10mm Aluminium Frame

Made to measure wardrobes running Gear Durability

All our made to measure wardrobes wheels and guides are cycle tested to 100,000 opening and closing actions in accordance with ANSI BHMA A156.14, This is an American National Standard, created in conjunction with Builders Hardware Manufacturers Association. The reason we test to this standard is because it’s the most rigorous sliding wardrobe door standard in the world, and enables our hardware to be sold to the contract market in the USA.

Made to measure wardrobes soft close durability

Our soft close system is tested to 40,000 open and closing actions in accordance with the German LGA Quality Directive, and RAL-GZ430 and DIN EN14749.

Minimum Door width for use with slow closure is 610mm.

Sliding Wardrobe Door Framing

All our made to measure wardrobes door frames are manufactured from either high grade roll formed steel, or extruded and anodised aluminium 6063-T5. This ensures a lifelong sturdy frame to your door, and will not be prone to damage or warping like some lower quality chipboard or MDF framed doors. They also have the advantage over wood in that they will not bow over time.

Made to measure wardrobes top and Bottom Tracks

Top and bottom tracks are also manufactured from either high grade roll formed steel, or extruded and anodised aluminium 6063-T5.

PLEASE NOTE-TRACK SETS HAVE TO BE CUT TO SIZE WITH A HACKSAW BY YOUR INSTALLER AT THE TIME OF INSTALLATION.

Sliding Wardrobe Door Mirror and Gloss Glass

High gloss glass panels are lacquered on the reverse face, to provide the highest quality gloss surface panels on the market. Mirror is high quality silver coated. All mirror and glass panels are safety laminated to pass BS6206, and Class 2B2 BSEN 12600. This ensures that you cannot fall through our glass or mirror panels, and if they were to break, then they crack in safe manner.

FSC Environmental Panels

All our panels are manufactured from FSC certified timber and particle board. FSC is the Forestry Stewardship Council certificate that guarantees our products come from environmentally managed sustainable forests.

Sliding Wardrobe Door Safety

As well as all our glass panels being safety laminated, our bottom wheels also come with an ‘anti jump’ device (shown in red in picture). This locks the wheel in the track to stop doors jumping clear of the track making our product the safest system on the market.

Dimensioned Cross Section

All dimensions in mm, and are nominal (i.e. subject to manufacturing tolerances). Soft close reduces available height adjustment by approximately 10mm. Aluminium and steel tracks are approximately the same dimensions.

- Cut the tracks

Carefully measure the width of the opening at top and bottom, and reduce the lengths measured by about 2-3 mm. Measure off the required track length, marking the future cut line on the tracks. Use a fine-toothed metal cutting saw to cut off the redundant part of the tracks.

Advice:The tracks to be installed should be about 50 mm longer than the opening width. This spare length will make it possible to avoid measurement errors and it is easy to trim. Take care not to damage the track surface while cutting. In order to facilitate top track cutting, insert 38 mm thick wood blocks or a reversed piece of track into the track. This will prevent track deflection during the cutting process.

2. Install the top track

Fix the top track with screws, offsetting its flat surface by 5 mm from the door face (inwards). Install the top track with the shade line facing forward in order to mask ceiling irregularities. If a multiple-track system is installed, fix the other tracks so that they fit tightly against each other along the entire length.

Advice: Before you start installation use a detector to make sure there is no electrical wiring at the screw fixing points. Avoid applying excessive force when tightening screws to prevent track deformation. Use flat-head screws for best results. The surface to which the track is fixed must not be curved.

3. Install the door

Lay the bottom track on the floor, offsetting it about 27 mm from the door face (inwards). Use a Philips screwdriver and the adjusting bolt to move bottom rollers out about 10 mm. Fully insert the door leaf in the top track, taking care not to damage the bottom rollers, then align the bottom end of the door leaf with the bottom track and slowly lower the leaf, letting the rollers snap into the track guides.

Advice: Before you install the doors, put a cardboard sheet on the bottom track to prevent damage to track surface. When the doors are already in position, remove the protective cardboard.

4. Install the bottom track

Use a level to make sure the door is exactly plumb; move the bottom track as necessary. Check if the door travels smoothly along the entire width of the opening. Having precisely set the bottom track, fasten it to the floor. Having installed the track, put the other door leaves in their respective tracks.

Advice: Before you fix the bottom track, make sure that it is positioned exactly parallel to the top track. With soft floor covering, before you fix the bottom track, cut out a strip of about 55 mm in width and replace it with a 55 mm timber batten. Alternatively, put a 100 mm floor batten between the floor covering and the bottom track. Avoid applying excessive force when tightening screws to prevent track deformation. Use flat -head screws for best results.

5. Adjust door position

Adjust door position by means of a Philips screwdriver and the adjusting bolts in the bottom rollers so that the doors fit tightly against the wall along the entire length. Door-to-floor clearance is adjustable between 10 and 40 mm (2 to 32 mm from the bottom track

Step 1

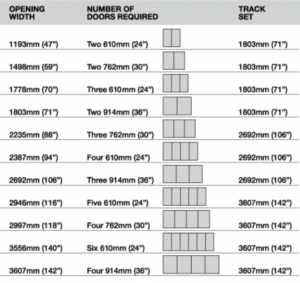

Begin by measuring your opening space. All doors fit a maximum opening height of 2260mm with a maximum opening width of 3607mm. Doors are available in up to three widths(610mm, 762mm, 914mm).

Please note. Doors don’t com in all three widths. Pleas make sure that you are aware of this (selecting your door first) before measuring up.

If there is a difference between the measurements of heights A, B or C, this means that yoor ceiling and floor are not parallel. Your track-set will allow for a difference of up to 15mm, but if the difference exceeds this you will need to make ajustments to your ceiling walls. (see diagrams 1b, 1c & 1d).

This can easily be done using our accessories listed on the previous page (Space blocks for under 127mm or the Open height reducer for gaps exceeding 127mm).

Step 2

Select and fit your Storage System

Begin by measuring your internal space. When fitting the Aura Storage system, decide whether you want the 550mm or 900mm wide shelves or drawer units as this may effect your door choice. Lay the components out first to ensure they fit your space. (All storage solution components come with detailed instructions).

Step 3

Build the opening for your doors

All doors are made to fit a standard opening height of 2260mm including track. Higher ceilings can be reduced using spacer blocks or opening height reducer.

Step 4

Calculate your door requirements

The number of doors you will need will deppend on your opening width. Refer to the calculation table below for additional information.

Standard Door Technical Specifications

- Top Track with Fascia and Top Slide Guides

- No Soft Close

- If purchasing `Soft Close` Upgrade the opening height should be 2286mm

- Sized to suit an opening height of 2260mm

- Available door widths of 610mm (24inch), 762mm (30 inch) and 914mm (36inch)

- When installing, the Floor Track should be fitted back level with the back of the Top Track

- Door Frame widths and overlaps between front and rear doors:

Generally we recommend that the overlap between front and rear doors is the same as the width of the door frame. We do this for aesthetic reasons only, so the amount of overlap is really your choice. Choose more or less overlap to make standard doors fit smaller or larger openings. You may notice that the door visualizer shows no overlap. This is just due to limitations in the software.

Overlap and door frame widths:

HERITAGE = 26mm Steel Frame

CLASSIC = 35mm Steel Frame

REFLEX MINIMAL = 12mm Aluminium Frame

SHAKER = 75mm Steel Frame

HERITAGE LOFT = 27mm Steel Frame

Sliding Wardrobe Door Running Gear Durability

All our sliding wardrobe wheels and guides are cycle tested to 100,000 opening and closing actions in accordance with ANSI BHMA A156.14, This is an American National Standard, created in conjunction with Builders Hardware Manufacturers Association. The reason we test to this standard is because it’s the most rigorous standard in the world, and enables our hardware to be sold to the contract market in the USA, and enables us to confidently guarantee our running gear for 10 years of continuous use.

Sliding Wardrobe Door Framing

All our standard sized door frames are manufactured from high grade roll formed steel. This ensures a lifelong sturdy frame to your door, and will not be prone to damage or warping like some lower quality chipboard or MDF framed doors. They also have the advantage over wood in that they will not bow over time.

Sliding Robes Top and Bottom Tracks

Top and bottom tracks are also manufactured from high grade roll formed steel. Anodised aluminium for Reflex and Glam ranges.

Sliding Robes Mirror and Gloss Glass

High gloss glass panels are lacquered on the reverse face, to provide the highest quality gloss surface panels on the market. Mirror is high quality silver coated. All mirror and glass panels are safety laminated to pass BS6206, and Class 2B2 BSEN 12600. This ensures that you cannot fall through our glass or mirror panels, and if they were to break, then they crack in safe manner.

FSC Environmental Panels

All our panels are manufactured from FSC certified timber and particle board. FSC is the Forestry Stewardship Council certificate that guarantees our products come from environmentally managed sustainable forests.

Safety

As well as all our glass panels being safety laminated, our bottom wheels also come with an ‘anti jump’ device (shown in red in picture). This locks the wheel in the track to stop doors jumping clear of the track making our product the safest system on the market.

Dimensioned Cross Sectional Drawing

All dimension in mm. Dimensions are nominal (i.e. subject to manufacturing tolerances).

a

STANDARD SIZE DOORS = 2.5 – 3 weeks

MADE to MEASURE DOORS = 2.5 – 3 weeks (ranges – Heritage, Classic, Shaker, Mirage, Glam & Heritage Loft)

MADE to MEASURE DOORS = 4 weeks (ranges – Budget, Tess Minimal, Neptune, Jupiter Angled & Alpha)

INTERIORS = 2.5 – 3 weeks (ranges – Aura, Standard & Basic)

INTERIOR = 3-4 weeks (range – Panelux)

BEDROOM FURNITURE = 2.5 – 3 weeks

GLASS DOORS = 2.5 – 3 weeks

Our delivery rates to the England, Scotland & Wales is only £60.00 and to N. Ireland & Rep. of Ireland £90.00 This is a flat rate, however for some smaller individual components, we can arrange to deliver using a courier. It is your (the customers) responsibility to check that large items can be delivered to the intended room for the product.

We cannot be held responsible for product not fitting through small doorways, into lifts or up narrow staircases. If in doubt, please contact us for exact dimensions of your chosen product.

Delivery of your sliding wardrobe order will take generally 2.5-3 weeks for standard doors, and normally 2.5-4 weeks (depending on door range-as above) for Made to measure orders.

After placing and paying for an order, we will manufacture or pick you product, and then deliver to our home delivery company, who will then call (on the number you provide) to arrange a delivery time and date.

They will aim to give you one weeks’ notice to allow you to make arrangements for receipt.

Booking an Installation date with your Installer

We advise, in the unlikely situation that your order maybe damaged in transit or have a shortage, that you do not confirm an installation date with your installer until you have received your order & checked that all pieces are present & correct, this will ensure that the installation will run smoothly.

We are a supply only company & have nothing to do with the installation of our products or timescales.

Checking Your Order is of Highest Importance!

This is a large glass product, and occasionally there will be damage in transit, so please make sure:

- That someone is present to receive the delivery and sign for it.

- We highly recommend that you unwrap and inspect glass products before signing the delivery note; the driver will wait while you do this. The product is shrink wrapped in clear polythene to help with this process.

- Where this is not possible, or with multiple boxed products, the delivery note must be signed “contents unchecked”, most importantly any evidence of ripped or disturbed packaging must be noted.

- Any claims of missing items or damaged items must be made within 48hrs of the delivery provided that the delivery note was signed “contents unchecked”.

Any claims after this 48 hour period cannot be accepted. Damages must be reported by E-MAIL ONLY to sales@slidingrobesdirect.com

Any damage claims where the delivery note has been signed “received in good condition” cannot be accepted.

Deliveries are to ground floor only and then to a room of your choice, where it is safe to do so.

If for any reason an item is damaged in transit, we will remake and deliver that item free of charge and at upmost priority

Standard Size doors & Interiors

Standard size sliding doors and Interior components can be returned or exchanged if not required, the purchaser pays the collection cost of £ 60.00 (UK Mainland)

We are unable to accept the return of any product which has been opened from the original factory packaging.

The initial £ 60.00 (UK Mainland) delivery charge is non-refundable.

Standard products – if incorrect or not wanted when received then we need to be notified by e-mail within 14 days of receiving the goods.

Made to Measure doors cannot be returned or exchanged as these are custom made to each purchasers specifications.

Recently I purchased a sliding door wardrobe. Thank you very much for the prompt delivery and the wardrobe look great in my flat. Excellent service.

Really appreciate your help and the great customer service that we have received from you.

Great Service!! The delivery was an excellent service, plus the quality is really great. The oak doors look fantastic next to our oak flooring. Thank you so much for all your help. Looking forward to the final phase, in the new year, so I can order the last three!

Thank you, I am more than made up with the doors and customer service. Pass on my thanks to those involved.

Thanking you for our lovely sliding wardrobe doors which have now been installed and finish our bedroom to perfection! So I have nothing but gratitude for your company and to the staff for their efforts in providing quality goods with an excellent back up service, well done all.

We were impressed with the mirrored wardrobes we received for our daughter’s room so have ordered for our room now.